Safety Glass & Decorative Glass Solutions

Why Choose Jinjing?

Entire glass industry chain production and original factory processing ensure high quality control of the glass from the upstream: 13 float lines, 20 million ㎡ online Low-E production capacity & 10 million ㎡ offline Low-E line, 2 glass process bases

Various tinted glass, high quality ultra clear glass, from triple/double/single silver Low-E glass to online Low-E glass, rich glass selections can meet different design & performance requirements.

Lisec, Bottero,Glaston,Bystronic…… Advanced processing equipments ensure best quality & performance of the glass.

$15 million/year R&D expenditure, 6000 square meters laboratory. A strong R&D and technical support team provides customers with professional energy efficient glass solutions.

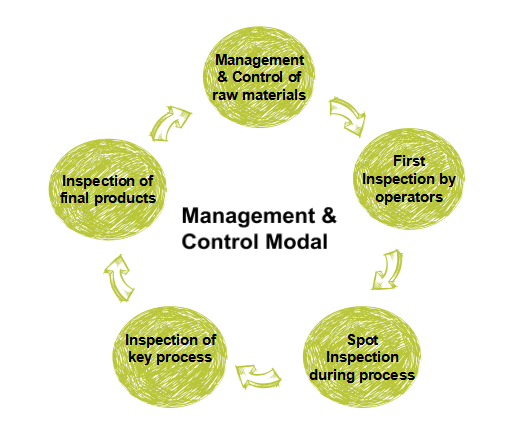

Complete quality control system to ensure good quality for glass units, from raw material to cutting, edge grinding, tempering, laminating and insulating.

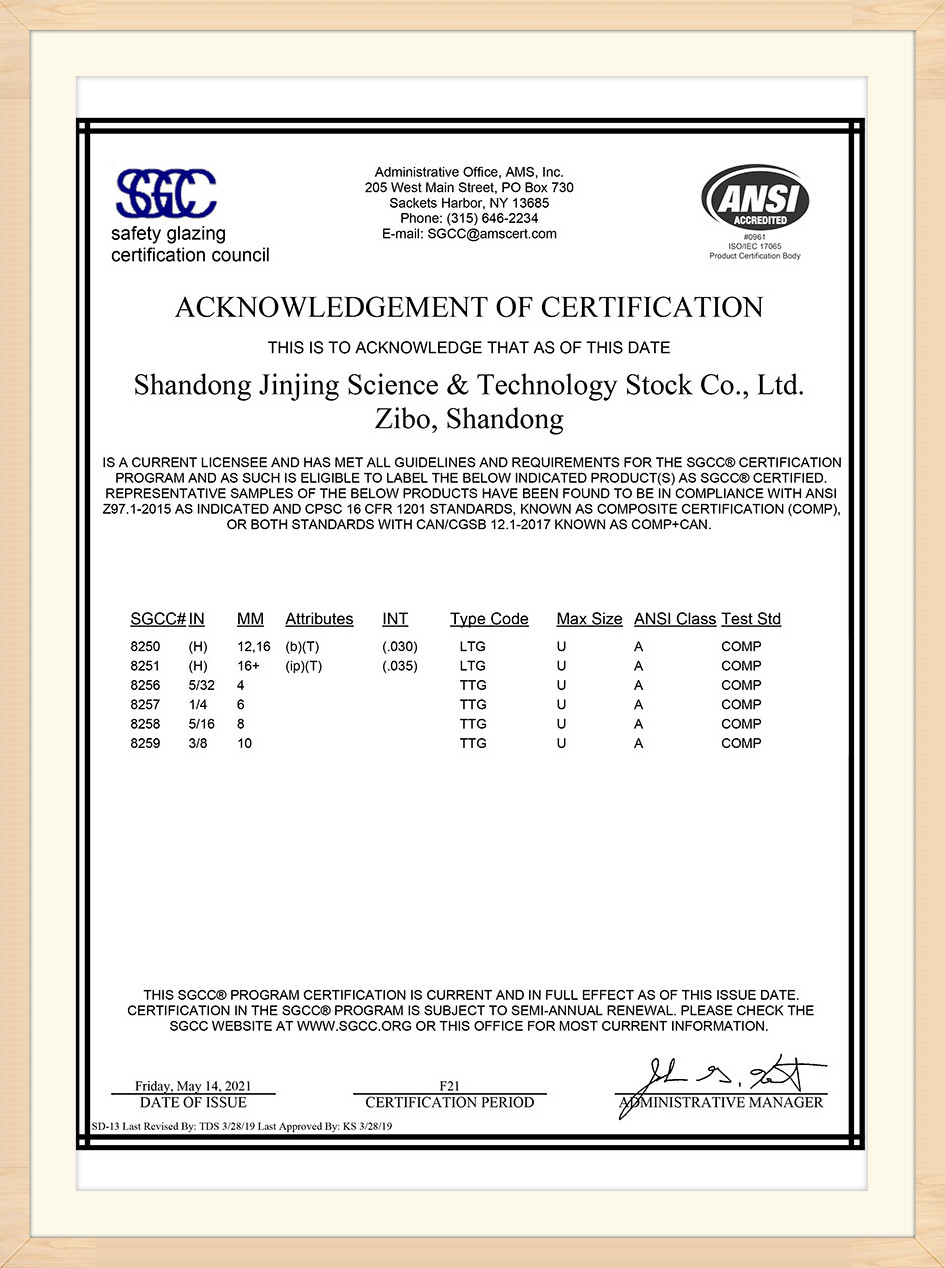

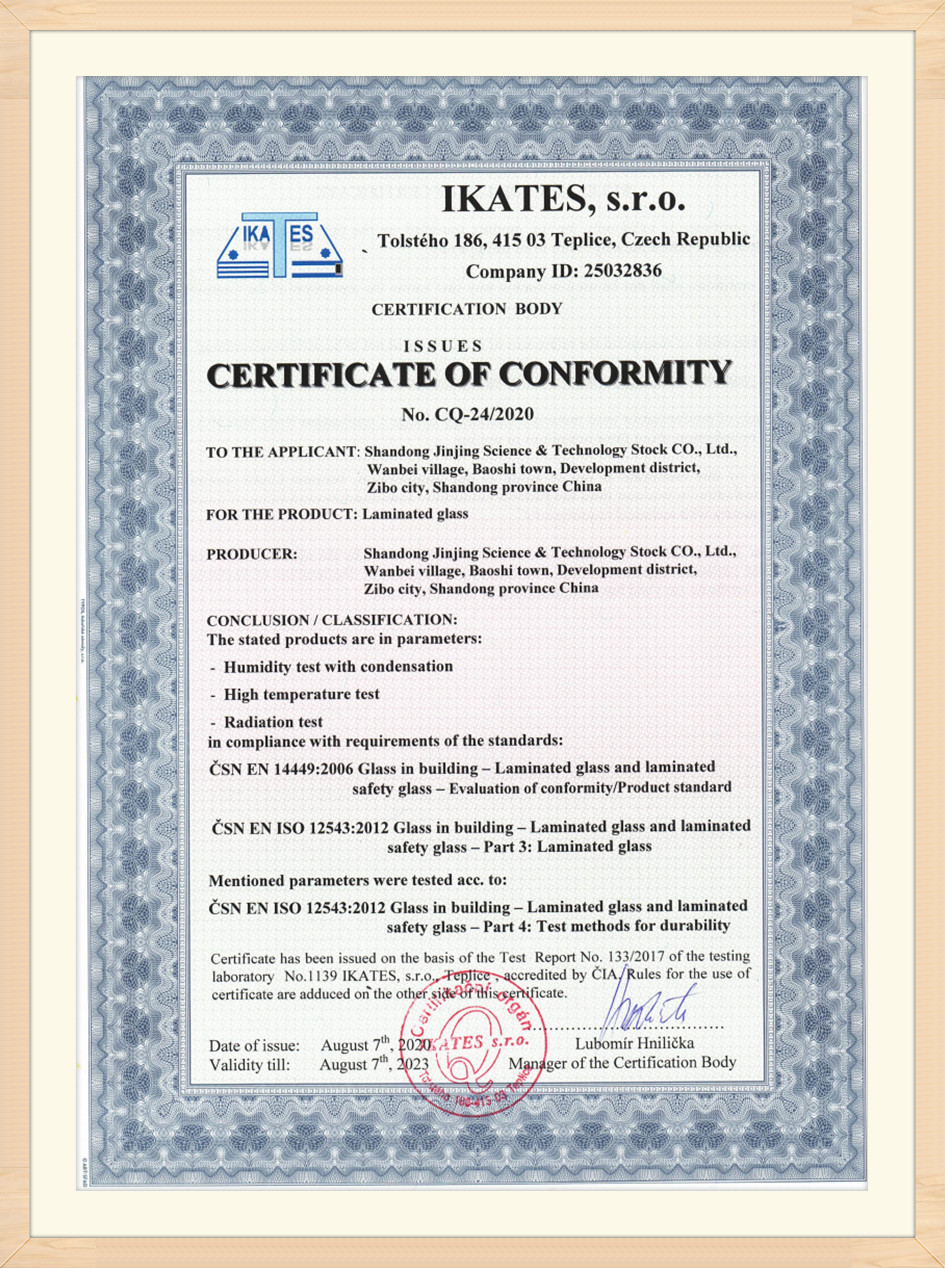

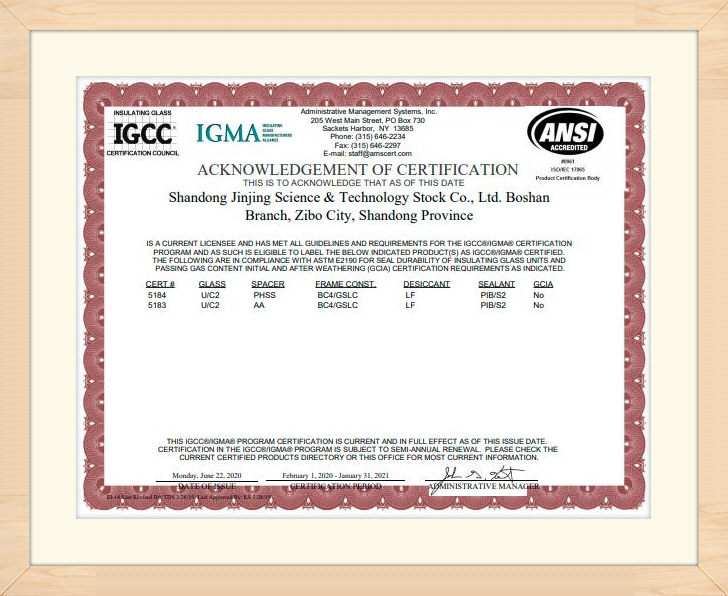

Related Certificates:

Capabilities

High performance fully automatic cutting & grinding lines from loading to breakout with any required shape and size.

Lisec Automatic Cutting Line

Bottero Automatic Cutting Line

Bottero Grinding Line

Bentler Grinding Line

Waterjet cutting & CNC machines for customized glass shapes & edge working.

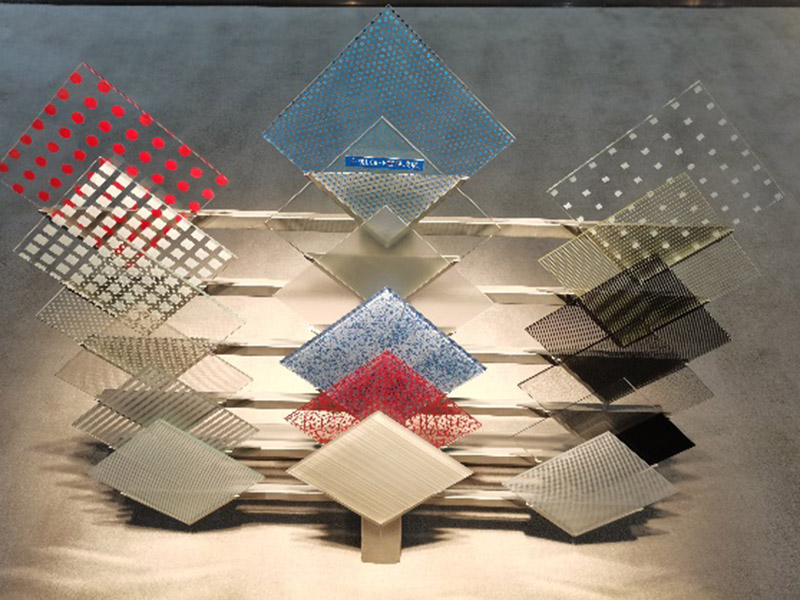

Silk printing, digital printing and painting, more choice for design.

Painting Line

Silk Printing Line

Digital Printing Line

Samples

8 tempering furnaces with yearly production capacity over 15 million ㎡. Complies with European EN12150 and North American SGCC norms regarding flatness, strength, fragmentation, dimensions and tolerances etc.

Glaston Toughening Furnace

Tam Toughening Furnace

Tucheng Toughening Furnace

Jinglass Toughening Furnace

Heat Soak Test Furnace

Depending on the design & safety needs, Jinjing offers laminated glass made with sheets of annealed, tempered, heat strengthened and coated glass, which exhibits important structural performance and safety features along with other benefits, such as Safety / Security / Sound control/ Solar control, etc.